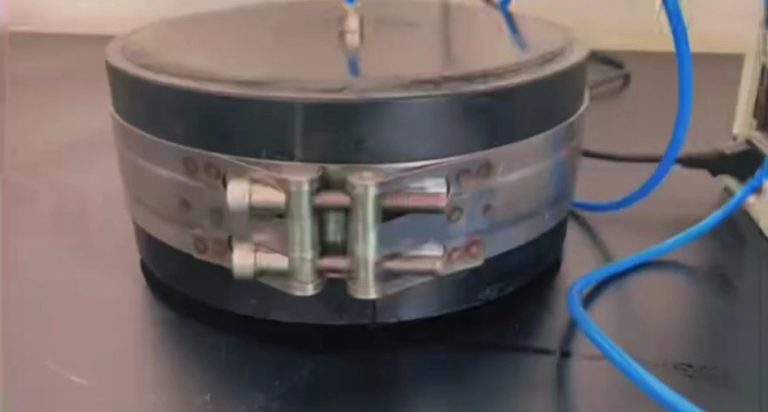

SAE type F hose clamp is the most commonly used American type hose clamp.It’s also one kind of worm drive hose clamp.This blog is to show the main technical speficiations according to SAE J1508.

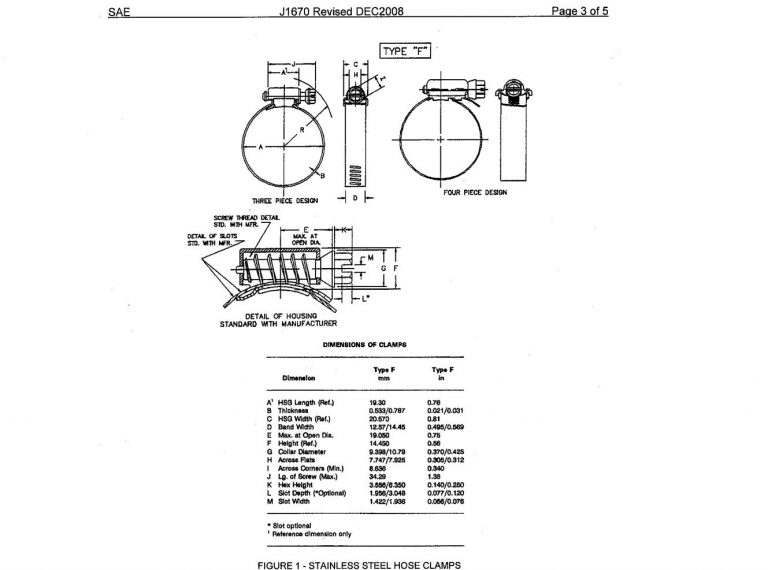

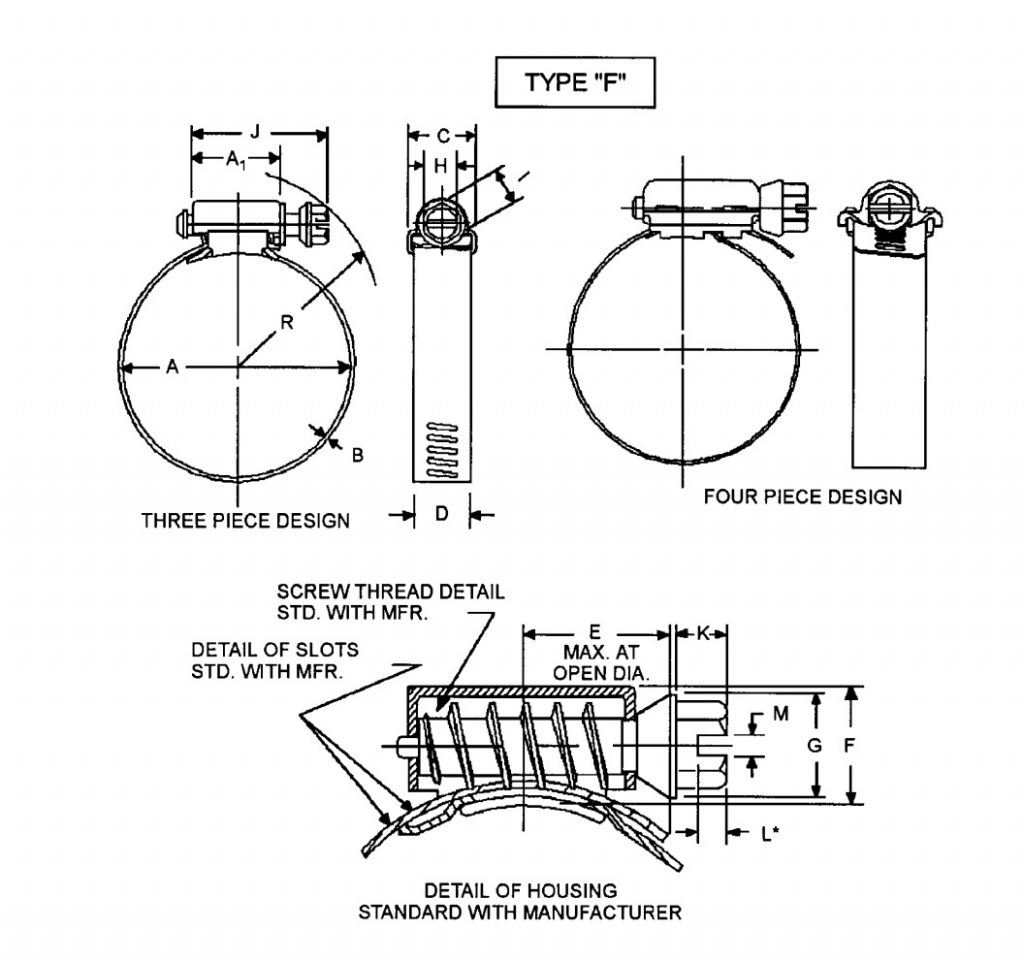

Drawing and specificaitons:

| Dimension | mm | INCH | |

| A | HSG Length (Ref.) | 19.3 | 0.76 |

| B | Thickness | 0.533/0.787 | 0.021/0.031 |

| C | HSG Width (Ref.) | 20.57 | 0.81 |

| D | Bandwidth | 12.57/14.45 | 0.495/0.569 |

| E | Max. at Open Diameter | 19.05 | 0.75 |

| F | Height (Ref | 14.45 | 0.56 |

| G | Collar Diameter | 9.398/10.79 | 0.370/0.425 |

| H | Across Flats | 7.747/7.925 | 0.305/0.312 |

| I | Across Corners (Min.) | 8.636 | 0.34 |

| J | LG. of Screw (Max.) | 34.29 | 1.35 |

| K | Hex Height | 3.556/6.350 | 0.140/0.250 |

| L | Slot Depth | 1.956/3.048 | 0.077/0.120 |

| M | Slot Width | 1.422/1.936 | 0.056/0.076 |

| SAE No. | A Diameter open mm | A Diameter closed mm |

| 06 | 19.8 | 11.2 |

| 08 | 23.1 | 12.7 |

| 10 | 26.9 | 14.2 |

| 12 | 31.7 | 17.5 |

| 16 | 38.1 | 20.6 |

| 20 | 44.4 | 20.6 |

| 24 | 50.8 | 26.9 |

| 28 | 57.1 | 33.3 |

| 32 | 63.5 | 39.6 |

| 36 | 69.8 | 45.9 |

| 40 | 76.2 | 52.3 |

| 44 | 82.5 | 58.6 |

| 48 | 88.9 | 65 |

| 52 | 95.2 | 71.4 |

| 56 | 101.6 | 77.7 |

| 60 | 107.9 | 84.1 |

| 64 | 114.3 | 90.4 |

| 72 | 127 | 103.1 |

| 80 | 139.7 | 117.3 |

| 88 | 152.4 | 130 |

| 96 | 165.1 | 141.2 |

| 104 | 177.8 | 156.9 |

Material

SAE type F hose clamp consist of Band,housing and screw.

Band material:

UNS-S20100, AISI Austenitic stainless grades 201; S30100, 301; S30200, 302; S30400, 304; and

S31600, 316; S43000, AISI Ferritic stainless grade 430; and heat-treated medium carbon steel.

Housing material:

Same as band, except unheat-treated carbon steel

Screw material:

UNS-G10060, AISI 1006—G10180, 1018; and G10211 10B21 carbon steels; S41000, AISI grades 410; S43000, 430; S30200, 302; S30400, 304; S30550, 305; and S31600, 316 stainless steels.

Torque

DURABILITY TORQUE

Screw threads and slots in the band shall show no evidence of deformation or

excessive wear when clamps are tightened once on a steel mandrel to the applied screw torques in Table

| Carbon | Carbon | 410SS | 410SS | 305SS | 305SS |

| mm | inch | mm | inch | mm | inch |

| 5.65 | 50 | 6.78 | 60 | 6.78 | 60 |

FREE TORQUE

With the band fully engaging the screw, the torque required to turn the screw four turns shall

not exceed the values 4.5 N·m

INSTALLATION TORQUE

The suggested installation torque for a particular application must be established by

the supplier and the user, given due consideration to the physical configurations, properties of the materials

involved, and assembly tools to be used.Good practice indicates that type F clamp is installed at 50% to 70% of its rated “Durability Torque.